【Abstract】:

With the continuous attention of human beings to the environment, energy, green, low-carbon environmental protection and other issues, countries around the world have taken the recycling of plastics a

Time:2023/02/07As a leading enterprise in the plastics industry, Shandong Yingke Environmental Protection and Renewable Resources Co., Ltd. is a high-tech manufacturer engaged in the recycling, recycling and utilization of renewable resources. The company has innovatively opened up the whole industrial chain of plastic recycling and reuse, and is an original enterprise that perfectly grafts plastic recycling and fashion consumer goods.

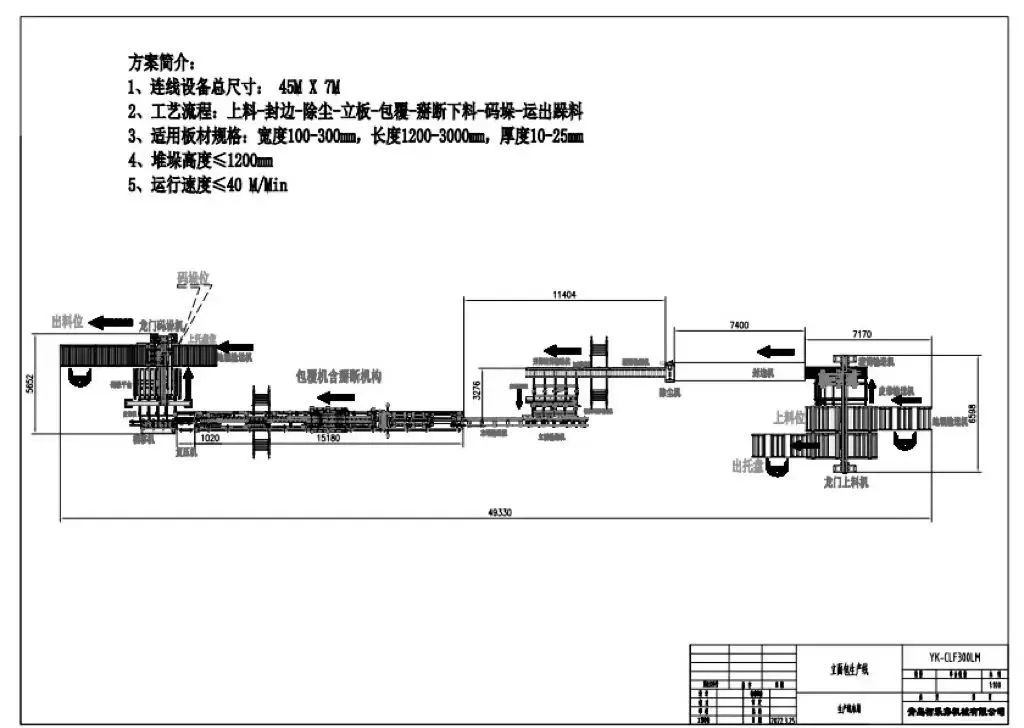

In order to actively respond to the "Opinions on Further Strengthening plastic pollution Control" of the Ministry of Ecology and Environment of the National Development and Reform Commission, Yingke Recycling will focus on the advantages of the whole industrial chain of resource recycling and recycling, and reach a strategic cooperation with Kloffer to purchase CLF-350LM numerical control vertical coating production line. Its production line mainly includes gantry feeder, motherboard conveyor, CNC coating machine, gantry palletizer, stacker and other main equipment, Help Ingke Recycling company to accurately and quickly build plastic recycling and recycling technology, and jointly contribute to further achieving carbon neutrality and sustainable development of the earth!

After the CNC vertical coating production line was officially put into use, it not only saved 80% of labor costs, but also ensured high efficiency and high-quality production capacity, and improved the overall production capacity of Yingke recycling enterprises. And in the whole link to achieve digital automatic intelligence, to further promote the enterprise into the "more, faster, better, provincial" model of plastic recycling in a new era!

Under the prevalence of "high quality and intelligent manufacturing", quality and efficiency are parallel, and the development of the plastics industry needs to strengthen "soft power" and temper "hard skills". Kloffer coating equipment has always followed the pace of development of The Times, according to the needs of enterprises, to create high-quality veneer equipment automation solutions. With each of our equipment, each solution, give different products colorful vitality!