【Abstract】:

"Design standardization, component prefabrication, and construction mechanization", the "industrialization of Chinese architecture" envisioned by the famous architect Liang Sicheng

Time:2023/02/07

Ronghua (Qingdao) Construction Technology Co., Ltd. is the first prefabricated building industrialization base in Shandong Province that is planned and designed according to the green two-star building standard and near zero emission. Since its inception, it has always adhered to the concept of "green development" as a guide, and constantly optimized the industrial structure, focusing on high production efficiency and high degree of automation. Join hands with Kloffer in the cladding production process in 2022 to create prefabricated building production.

After strict technical docking and negotiation, Klofer's equipment has reached the production needs of Ronghua Construction in automation and technology, and has become a powerful production force in the coating processing link. At present, Ronghua (Qingdao) Construction has CLF-PUR1300CNC automatic coating machine, which helps it to create high-quality building environmental protection new materials.

CLF-PUR1300CNC

Automatic coating machine

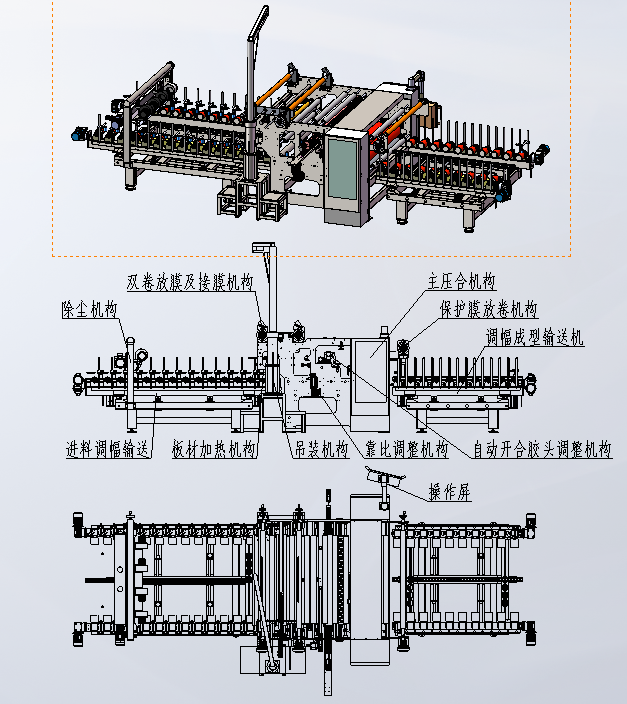

Equipment composition:

1- Brush dust 2- Fan dust removal 3-feed amplitude modulation 4-double unwinding structure 5- Film lifting device 6- Gluing device 7- Cutting device 8- Main press roller lifting device 9 - Plate heating device 10- coated amplitude modulation

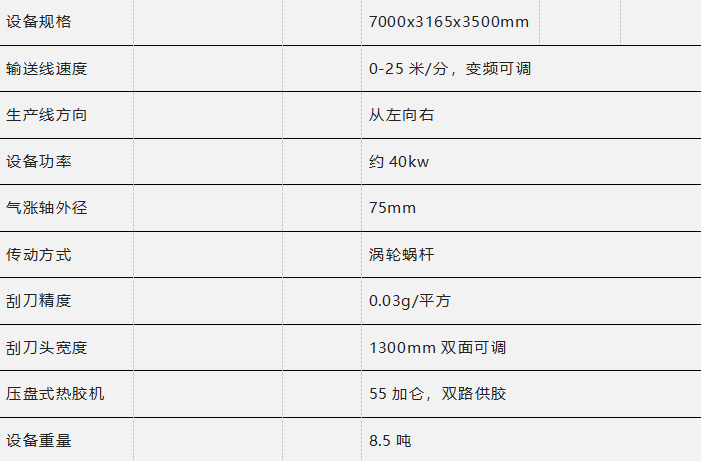

Technical parameters:

The whole body is welded by national standard square steel, CNC planer milling overall processing after aging treatment, high precision.

The surface of the fuselage is treated by sandblasting; Frame painting, wall panel spray treatment.

Feed AM transmission:

The frame is made of 150*100*5 rectangular tube and Q235A steel plate welded, CNC milling precision machining.

Two RV63+1.5Kw motors for transmission power; Motor 0.37KW drives brush roller and 4 hair dryers 0.3kw to dust sheet.

The 1.5KW servo motor drives the ball screw through the RV reducer to adjust the width of the conveying mechanism on both sides.

Main parts configuration requirements:

For us, the cooperation with Ronghua (Qingdao) Construction is not only a highly recognized performance of corporate strength, but also an opportunity for us to continuously improve innovation. In the future, we will continue to accelerate innovation in the coating process to achieve higher quality leading standards; At the same time, it also continuously promotes the development of the industry, and provides more professional and accurate technical support for creating low-carbon environmental protection and green development of prefabricated buildings.