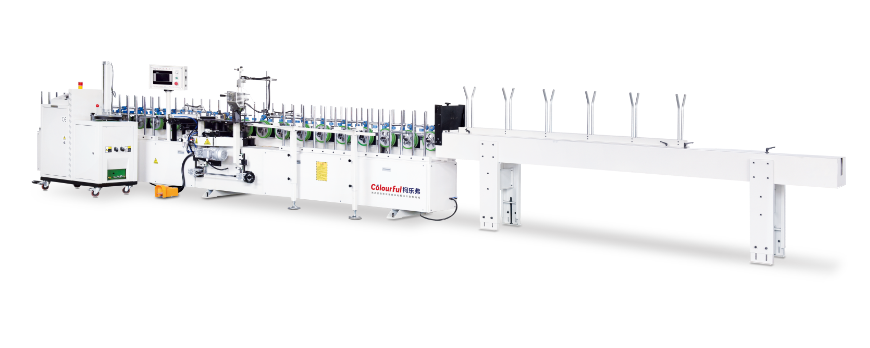

细节展示

Show Details

性能特点

Performance Characteristics

-

1. The pusher can be installed in different positions according to the length of the workpiece, and all processes are automatic and controlled by the machine panel.

-

2. The hot glue coating head of the side line is equipped with a line tray with manual height adjustment for automatic feeding. The rubber wheel is attached with a pressure zone, and has an independent electronic speed control to synchronize the main line and side line.

-

3. Continuous glue machine saving glue: to avoid the waste of rubber in the rubber hose and rubber bucket residues when changing glue, saving about 1 kg of PUR glue each time; Continuous production; The coating machine does not need to stop during the rubber changing process, and can be continuously glued and supplied for continuous production lines; Rubber pump protection; When the temperature of the heating disc is lower than the lower limit, the motor cannot start. Overtemperature alarm: when the temperature of the heating part exceeds the upper limit, the indicator lamp will alarm. Low glue level alarm: When the amount of glue in the glue bucket will be exhausted, the indicator light will alarm.

技术参数

Technical Parameters

|

|

|

|

Gross power

|

13.6 kw

|

|

Gross weight

|

3 tons

|

|

Overall dimension

|

9990×1150×1170mm

|

|

Production rate

|

0—30m/min

|

|

Working width (main line bar)

|

30—200mm

|

|

Working thickness (main line bar)

|

8—40mm

|

|

Working width

|

15—75mm

|

|

Working thickness

|

3—10mm

|