细节展示

Show Details

性能特点

Performance Characteristics

-

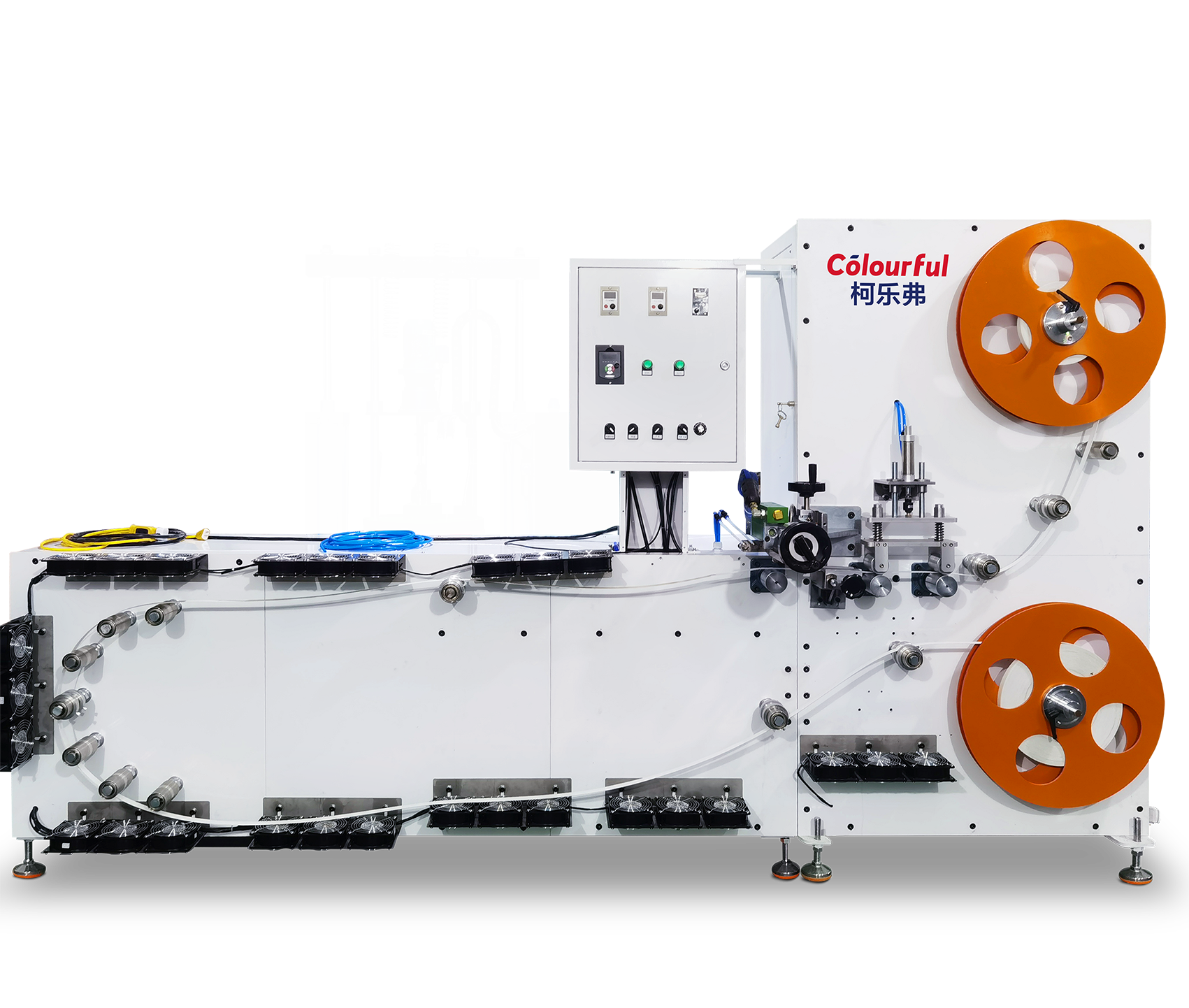

Edge sealing device

-

The edge sealing device is driven by servo motor;

-

Chuck type design, easy to put the sealing strip;

-

Scraper device:

-

For color film automatic gluing, gluing machine using continuous gluing machine heating gluing; Coating accuracy error 1g/ square;

-

The width of the coating head is 60mm adjustable (unilateral adjustment);

-

The surface of the scraper head is treated with Teflon, equipped with a scale, which is easy to set the glue width at a glance;

-

The upper and lower heights of the scraper head and the film guide roller can be fine-tuned to achieve the best gluing effect;

-

The blade is equipped with a pneumatic film roller and a spring buffer to keep the edge sealing strip smooth and stable before entering the blade;

-

Continuous gluing machine:

-

Continuous operation without stopping to change glue, no residual glue at the bottom, saving costs.

-

Device features:

-

1. Progressive heating melting: the heating disc is located at the bottom of the glue, when the heating chassis is heated, only the bottom layer of the rubber drum contacts with the heating disc, reaching the melting point and melting, the upper part of the rubber drum does not melt at this time, so as to meet the requirements of how much we need to melt in production;

-

2, coated with Teflon protective layer: the entire heating disc surface is coated with Teflon coating to prevent carbonization, ensure the best gum, reduce blockage;

-

3, stepless adjustment of glue output: precision gear pump operation control motor using stepless inverter speed regulation, can accurately control the output;

-

4. Humanized operation of the main motor: when the temperature of the heating disc does not reach the temperature of the temperature controller, the main motor cannot run, which solves the problem of misoperation of the operator;

-

5, the heating barrel is attached to the filter device, which can effectively filter the impurities in the glue, and achieve the effect of stable glue and no impurities.

-

6, the heating plate to the end of the signal indication, the main gas tank is equipped with a travel switch. When the pressure plate reaches the bottom of the bucket, the travel switch has a signal, and the signal light shows yellow, at this time, a new bucket should be prepared to put into the rubber bucket. A storage tank is provided at the bottom of the drum, which is sufficient for the production line to continue working before the new glue melts. Avoid the stop of rubber change.

-

7, continuous casting, improve production efficiency, suitable for mass production, continuous operation process.

-

PUR hot melt hose

-

1, the inner liner adopts imported Teflon tube, with good flexibility, anti-viscosity and high temperature resistance (up to 250 degrees), which can greatly reduce the carbonization phenomenon.

-

2, the heater uses the United States heating wire and high temperature resistant wire, evenly wound on the outer wall of the pipe, with good insulation and uniform heat conduction, high temperature resistance.

-

3, the use of high quality insulation materials to ensure insulation performance.

-

4, good bending performance, folding performance, relying on high-quality materials (folding continuous heating wire and high temperature resistance line), reasonable processing design, its maximum bending radius of up to 20cm.

-

5, length and other related parameters can be applied to all brands of hot glue in the world according to the use of demand.

-

Film guide device: a certain number of film guide rollers are installed on the body according to the track of the retracting and releasing edge sealing strip, and the film guide roller is equipped with a stop plate to ensure that the edge sealing strip does not run off; All are chrome-plated;

-

Cooling device: multiple fans are used to cool the edge sealing strip after gluing, so that the glue is completely cured before winding;

-

Receiving and sealing edge strip device: the gear motor with magnetic powder clutch is used for winding work; Achieve tensioning and stable winding during winding;

技术参数

Technical Parameters

|

Technical parameter

|

Technical parameter

|

|

Overall dimension

|

3200×1025x1865mm (L x W x H)

|

|

Line speed

|

20-30 m/min

|

|

Maximum gluing width

|

60mm

|

|

Diameter of edge strip

|

Max. 550mm

|

|

Gross power

|

Approx. 5kw

|

|

Gross weight

|

About 1 ton

|